What is critical defects, major defects and minor defects?

Defects found in inspection are classified into three categories: critical defects, major defects and minor defects:

1) Critical defects:

Critical defects could result in hazardous or unsafe conditions for individuals using or maintaining the product, as well as defects contravening legal regulations.

2) Major defects:

Major defects may affect the duration of product or reduce the ability to use the item (poor functioning, item incomplete or broken, etc.) or give it a flawed appearance which may affect the product value.

3) Minor defects:

Minor defects are unlikely to reduce the use of the product but nevertheless may influence the visual aspect.

E-best uses the MILITARY STANDARD 105E (MIL-STD-105E),tables, which are recognized standards by every industrial company.

This American standard now has equivalents in all national and international standardization organizations (ANSI/ASQC Z1.4, ISO 2859, NF06-022, BS 6001, DIN 40080).

This standard is a proven method to accept or reject a production lot by inspecting a randomly selected number of products.

This method is called 'AQL'(Acceptable Quality Level):

As a quality control company in China, E-best uses the Acceptable Quality Level (AQL) to establish a maximum allowable error rate or variation from the standard. Acceptance testing will cease immediately if the failure rate of the product being tested exceeds the minimum Acceptable Quality Level.

NB: It is important to note that Acceptance Sampling cannot provide 100% perfect products. The only way of achieving this is to produce 100% perfect products.

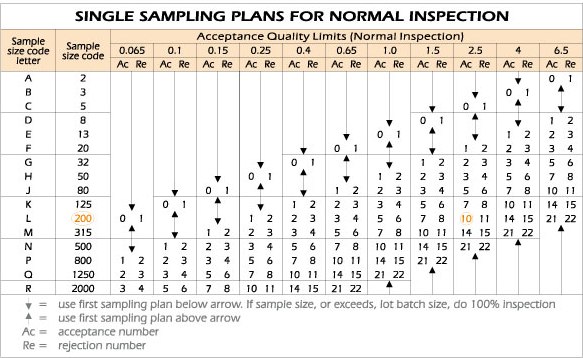

MIL STD 105E TABLE

Practically, E-best Quality Standards use the MIL-STD-105E tables that are summarized below:

What can I find out from the AQL tables?